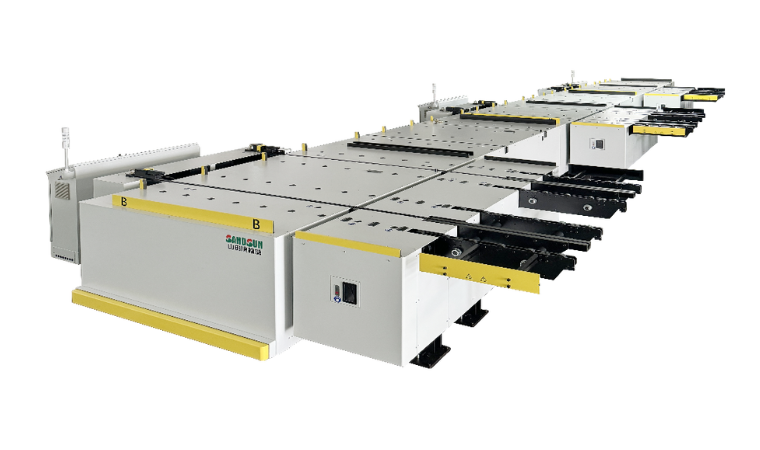

Mold Changing Star – Mold Cart for Three Machines and Six Molds

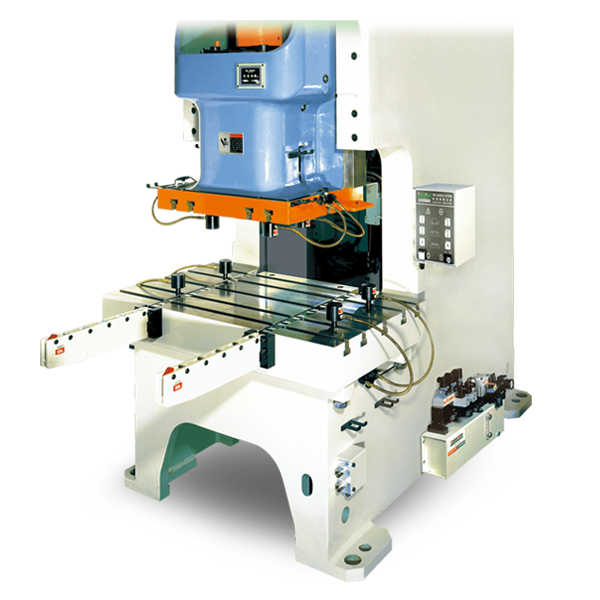

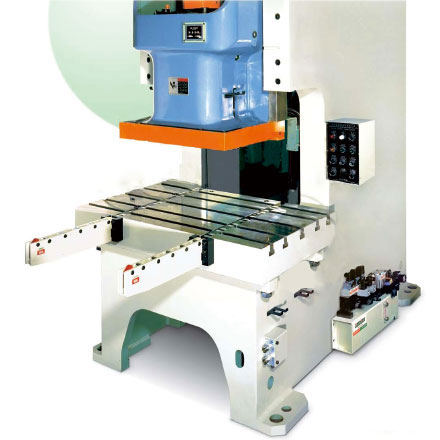

Under Industry 4.0, in order to meet the multiple patterns and small quantities of products and highly customized market demands, achieving rapid production, reducing manufacturing costs, and enhancing the safety of mold change are the keys to improving industrial competitiveness. SANDSUN recently cooperated with a well-known international air-conditioning manufacturer to increase its production efficiency and meet the needs for efficient mold change.

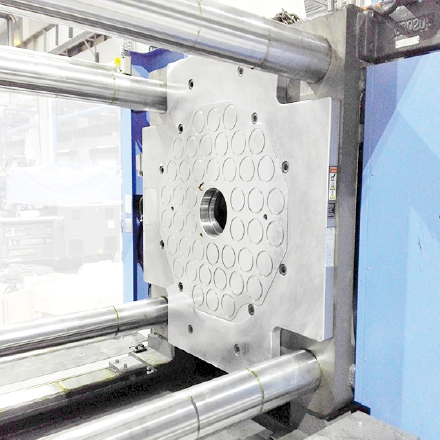

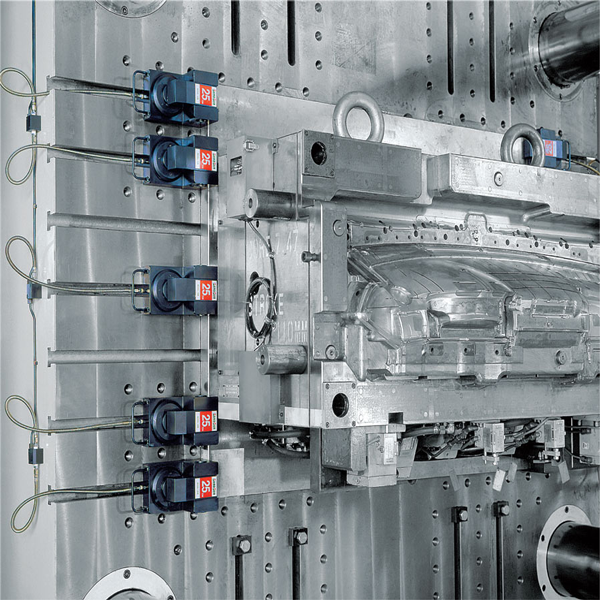

In response to the customer's challenge of limited space, SANDSUN designed a mechanism to connect three single-machine dual-mold Mold Cart, and integrates an interlocking electronic control system. This design enables the Mold Changer System to achieve fully automatic mold changing, reducing manual operations and increasing the mold changing speed. It is also equipped with multiple safety devices and interlocking electronic control systems to ensure safety during the mold changing process.

The application of the Mold Changer System effectively utilizes the limited space and realizes the simultaneous mold-changing and production operations of multiple machines. Continuous mold stamping technology increases production speed, and combined with the Mold Changer System, further shortens the mold change time. The automated Mold Changer System reduces downtime during the mold change process and improves overall production efficiency.

Automated systems reduce reliance on human labor and related costs. Efficient mold changes and production processes also reduce material waste, thereby lowering production costs. Through innovative design and technology application, SANDSUN not only overcomes the limitations of molds and factory space but also improves overall production efficiency and safety, helping customers maintain their advantage in the highly competitive market.