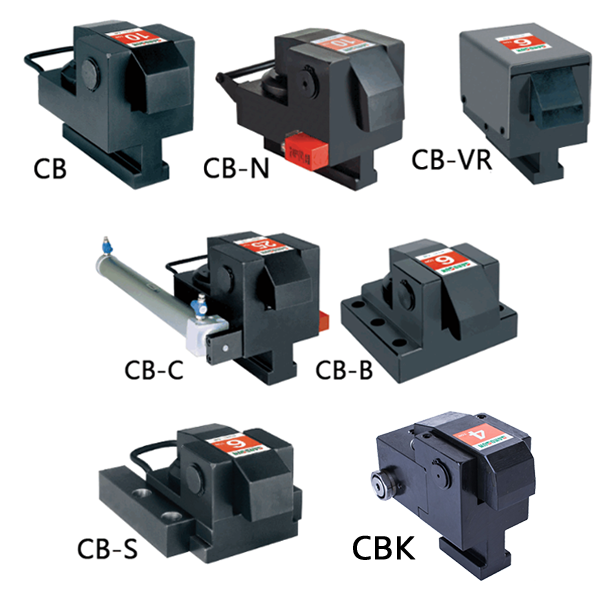

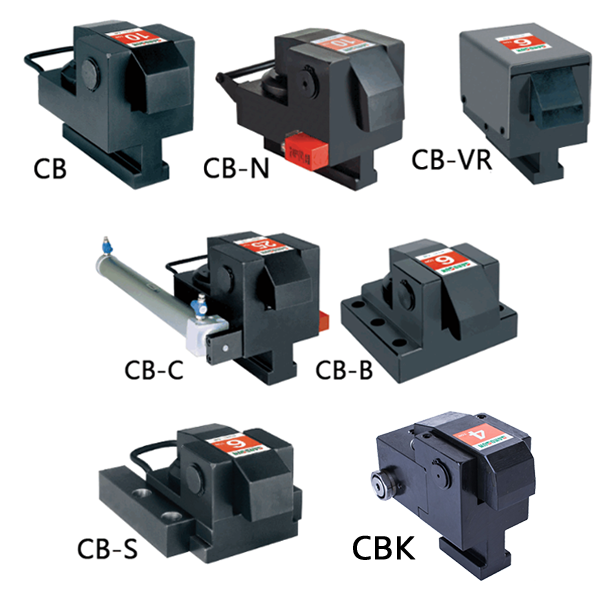

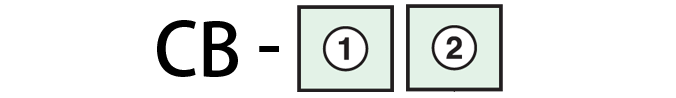

Model selection of mold clamp

|

①

|

②

|

|

Capacity of Clamp:2-50(tons)

|

-

Empty:Standard type

-

S: Slide moveable type

-

N: With sensor type/DC10~30V (NPN, 3-Wire)

-

V: Heat-resistant type

-

C: Pneumatic cylinder movable type

-

VR: Heat-resistant with cover type

-

B: Fixed type

|

INSTRUCTION OF SPECIFICATION

Unit:mm

|

MODEL

|

CB-2

|

CB-4

|

CB-6

|

CB-10

|

CB-16

|

CB-25

|

CB-50

|

|

Capacity of Clamp/*tons

|

2

|

4

|

6

|

10

|

16

|

25

|

50

|

|

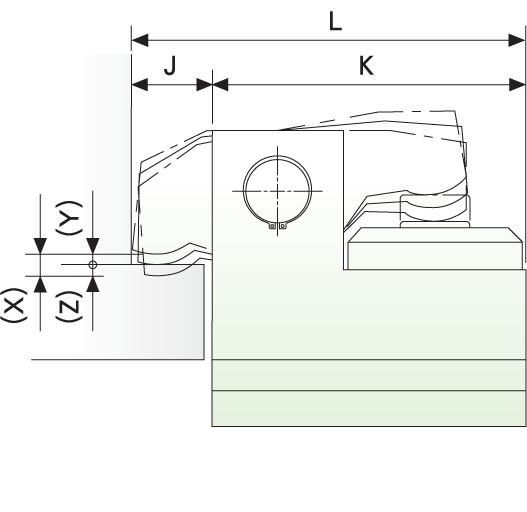

Total Stroke (X)/mm

|

8

|

8

|

8

|

8

|

8

|

8

|

10

|

|

Stroke of Clamp (Y)/mm

|

3

|

3

|

3

|

3

|

3

|

3

|

4

|

|

Preserved Stroke (Z)/mm

|

5

|

5

|

5

|

5

|

5

|

5

|

6

|

|

Total Volume/cc

|

7.5

|

13

|

21

|

38

|

55

|

98

|

220

|

|

The tolerance of template thinkness (H)

|

±2

|

±2

|

±2

|

±2

|

±2

|

±2

|

±2

|

*Hydraulic pressure: 250kgf/cm²

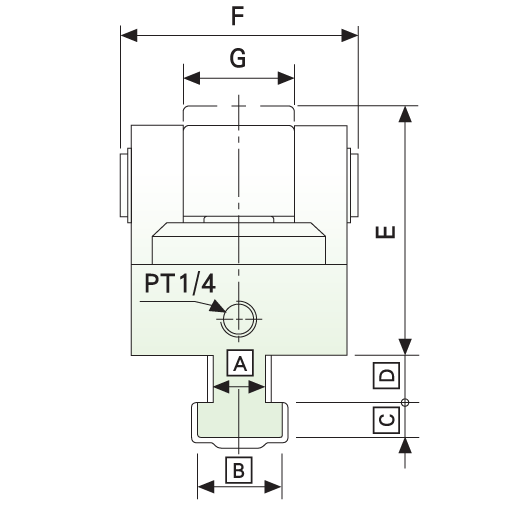

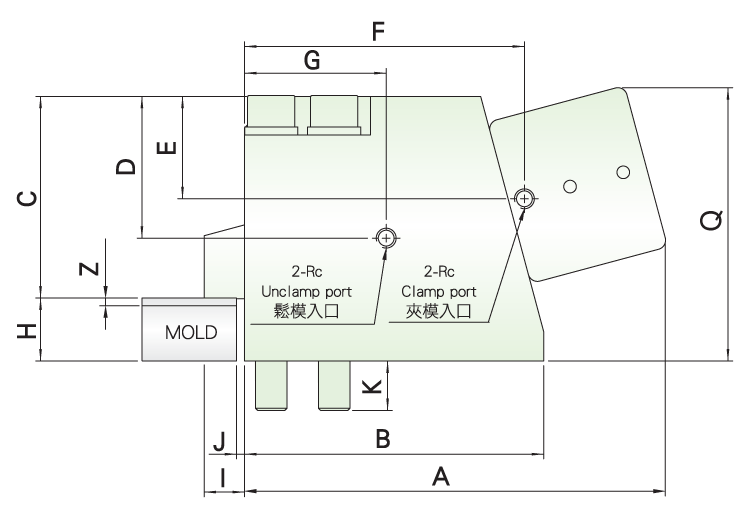

MODEL CB mould clamp

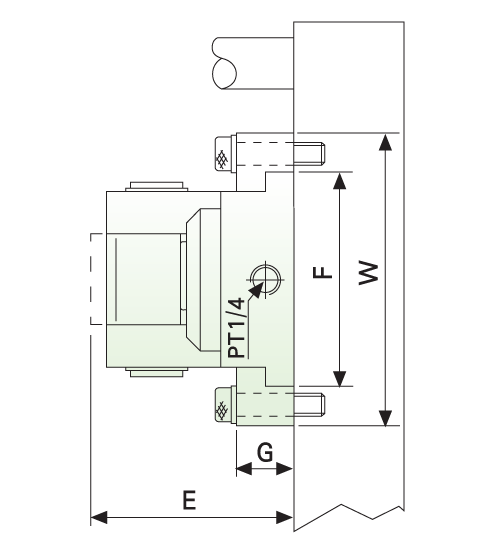

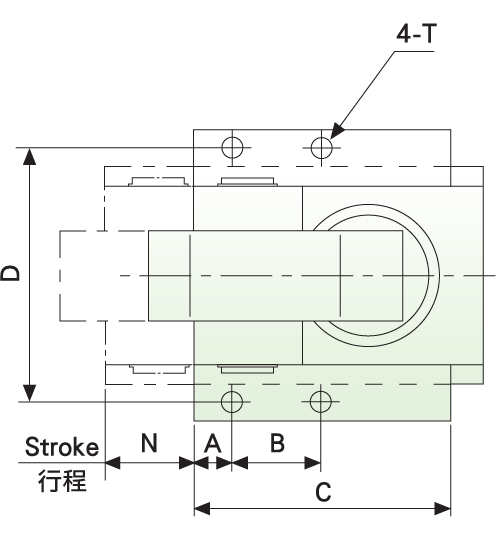

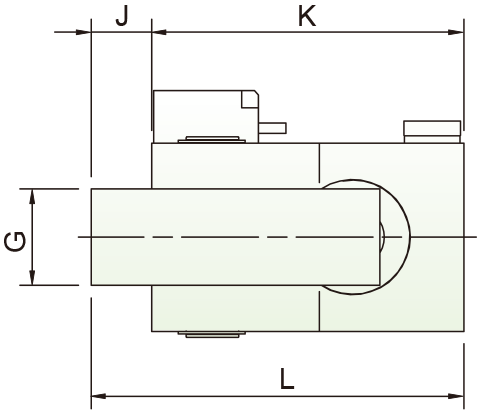

OUTLINE DIMENSIONS

Unit:mm

|

MODLE

|

|

CB-2

|

|

CB-4

|

|

CB-6

|

|

CB-10

|

|

CB-16

|

|

CB-25

|

|

CB-50

|

|

L

|

K

|

J

|

min. E

|

F

|

G

|

min.C

|

|

110

|

90

|

20

|

73

|

68

|

32

|

10

|

|

134

|

110

|

24

|

77

|

79

|

40

|

12

|

|

159

|

130

|

29

|

92

|

96

|

46

|

14

|

|

189

|

159

|

30

|

114

|

117

|

54

|

16

|

|

230

|

200

|

30

|

126

|

129

|

58

|

20

|

|

265

|

235

|

30

|

148

|

156

|

70

|

23

|

|

320

|

290

|

30

|

180

|

246

|

110

|

34

|

-

The size of clampsA B Cand D are made based on the size of T-slot.

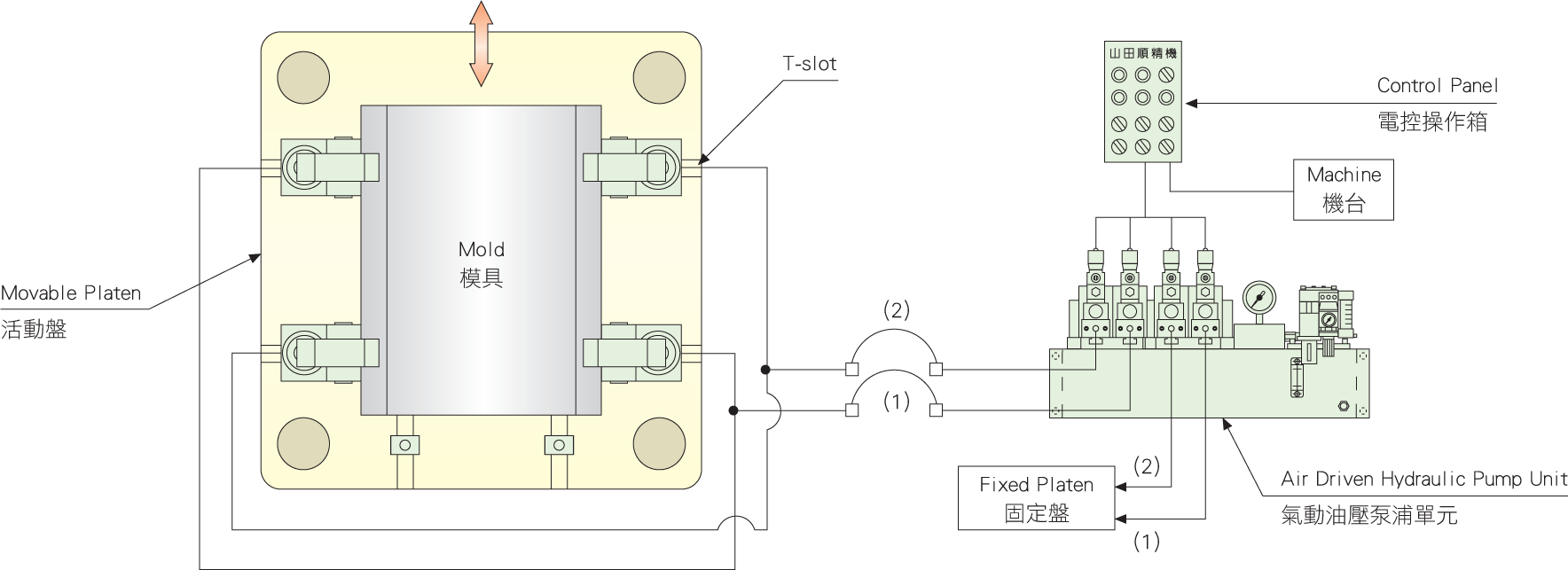

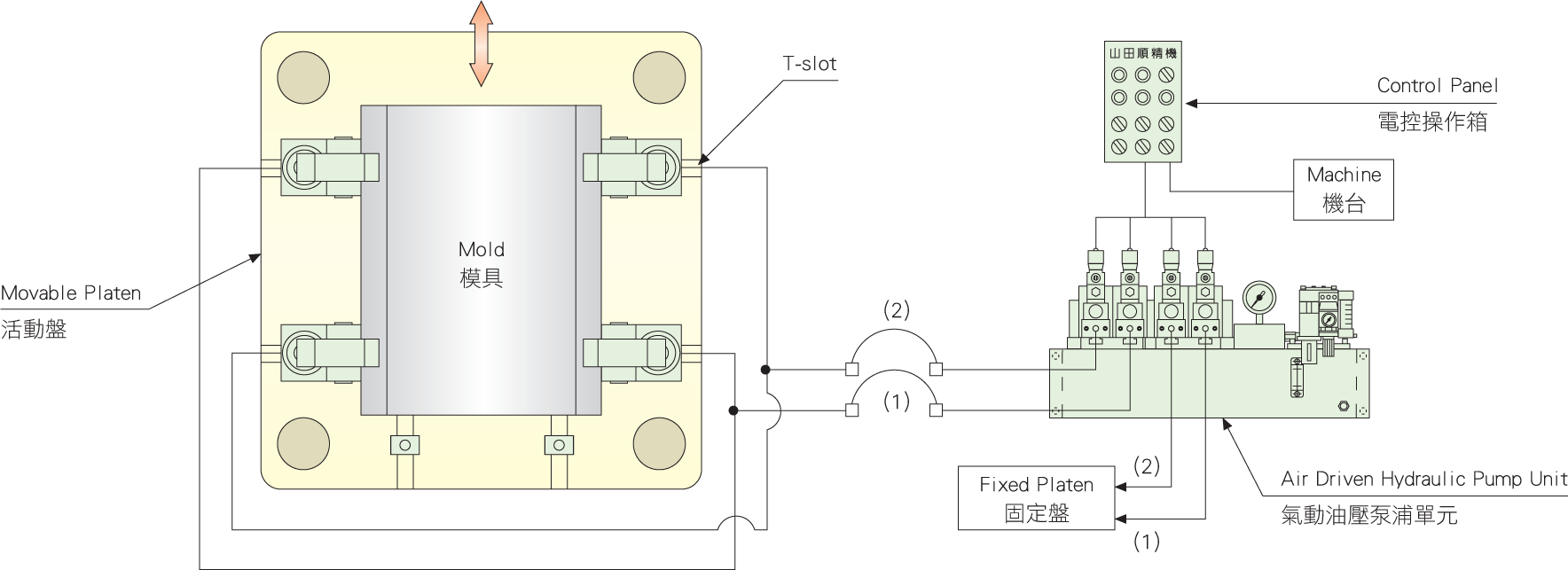

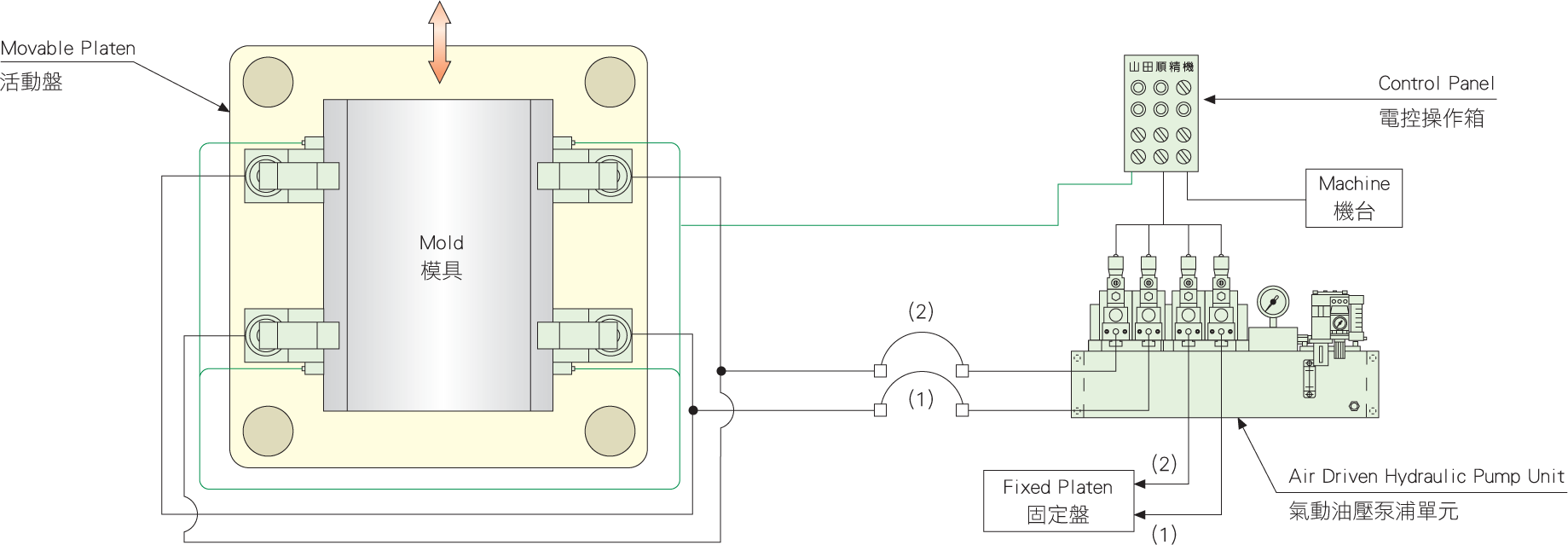

VERTICAL LOADING

-

Platen with T-slot

-

Optional for position checking sensor

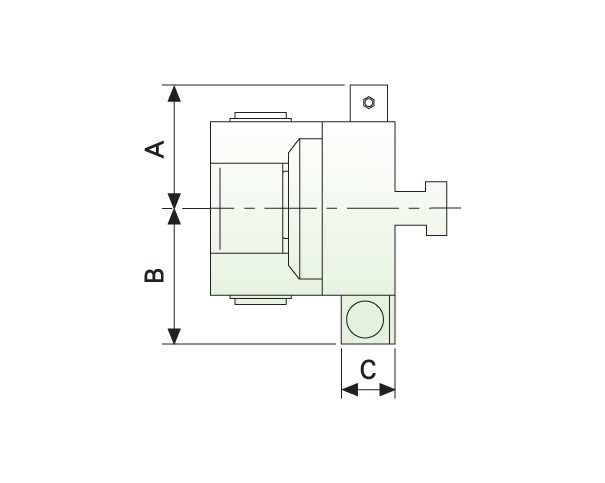

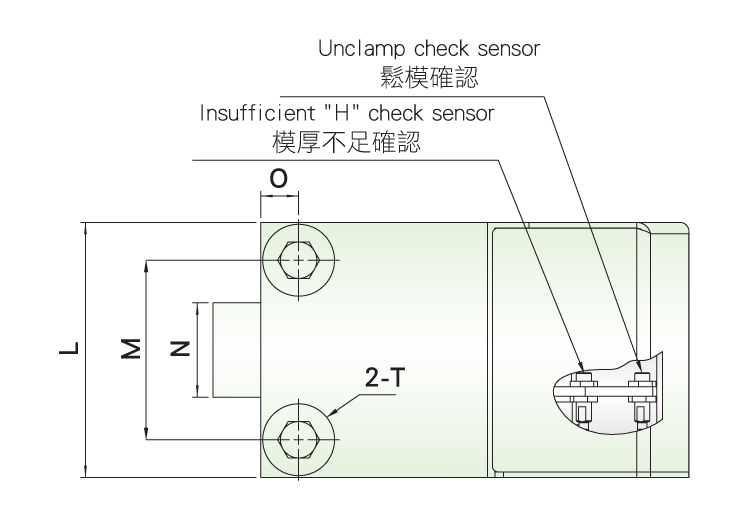

MODEL CB-N mould clamp

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CB-2N

|

|

CB-4N

|

|

CB-6N

|

|

CB-10N

|

|

CB-16N

|

|

CB-25N

|

|

CB-50N

|

|

A

|

B

|

min. E

|

G

|

J

|

K

|

L

|

|

56

|

34

|

73

|

32

|

20

|

90

|

110

|

|

61.5

|

39.5

|

77

|

40

|

24

|

110

|

134

|

|

70

|

48

|

92

|

46

|

29

|

130

|

159

|

|

80

|

58.5

|

114

|

54

|

30

|

159

|

189

|

|

86

|

64.5

|

126

|

58

|

30

|

200

|

230

|

|

99

|

78

|

148

|

70

|

30

|

235

|

265

|

|

145

|

123

|

180

|

110

|

30

|

290

|

320

|

VERTICAL LOADING

-

Platen with T-slot and manual clamp with sensor.

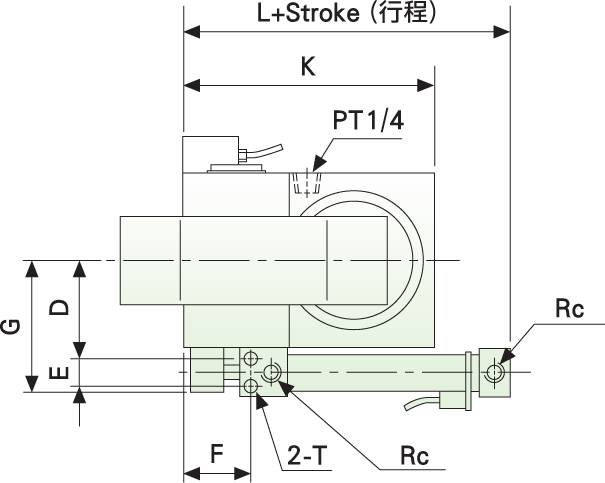

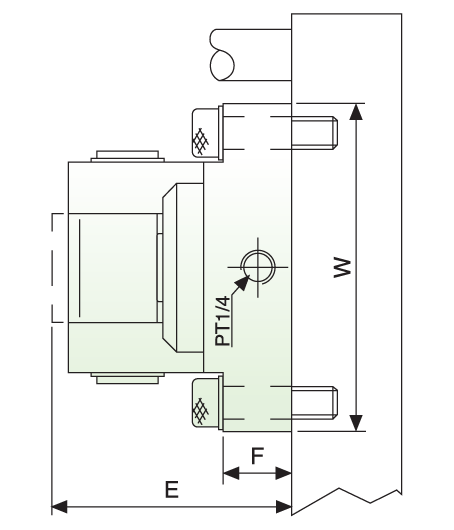

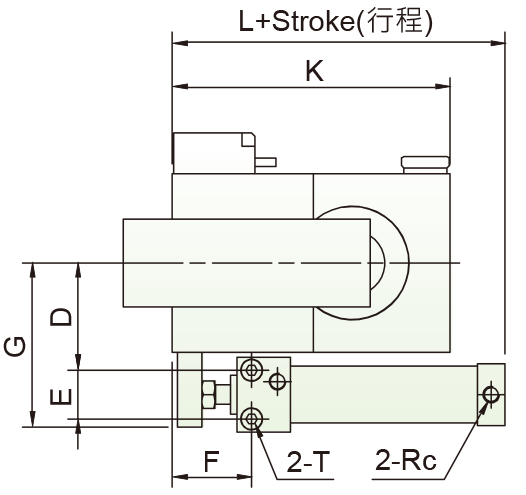

MODEL CB-C

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CB-2C

|

|

CB-4C

|

|

CB-6C

|

|

CB-10C

|

|

CB-16C

|

|

CB-25C

|

|

CB-50C

|

|

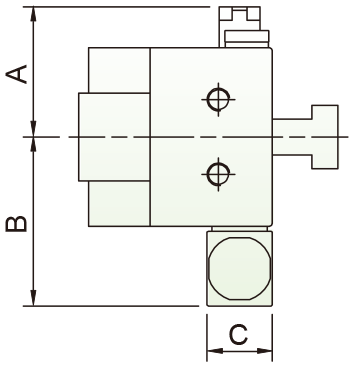

A

|

B

|

C

|

D

|

E

|

F

|

G

|

K

|

L

|

Rc

|

Tapping(T)

|

|

56

|

68

|

28

|

41

|

20

|

57.5

|

66

|

90

|

131

|

1/8

|

M6x12D

|

|

61.5

|

73.5

|

28

|

46.5

|

20

|

57.5

|

71.5

|

110

|

131

|

1/8

|

M6x12D

|

|

70

|

86

|

34

|

55

|

24

|

62.5

|

82

|

130

|

135

|

1/8

|

M6x12D

|

|

80

|

104

|

40

|

66

|

30

|

48.5

|

101

|

159

|

129

|

1/8

|

M8x16D

|

|

86

|

119.5

|

50

|

73.5

|

36

|

50

|

117

|

200

|

141

|

1/8

|

M10x20D

|

|

99

|

133

|

50

|

87

|

36

|

50

|

130

|

235

|

141

|

1/8

|

M10x20D

|

|

145

|

263

|

100

|

138

|

110

|

62

|

220

|

290

|

192

|

3/8

|

M16x32D

|

VERTICAL LOADING

-

Platen with T-slot and clamps moved automatically by pneumatic cylinder.

-

Another selection of clamping direction: left-right.

MODEL CB-S

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CB-2S

|

|

CB-4S

|

|

CB-6S

|

|

CB-10S

|

|

CB-16S

|

|

CB-25S

|

|

A

|

B

|

C

|

D

|

min.E

|

F

|

G

|

W

|

max. N

|

Tapping (T)

|

|

12

|

20

|

80

|

98

|

90

|

76

|

30

|

124

|

25

|

M10X20D

|

|

12

|

25

|

100

|

109

|

93

|

87

|

30

|

135

|

30

|

M12X24D

|

|

15

|

30

|

120

|

126

|

109

|

104

|

30

|

152

|

35

|

M12X24D

|

|

15

|

35

|

150

|

148

|

131

|

124

|

36

|

174

|

40

|

M14X28D

|

|

20

|

40

|

200

|

166

|

142

|

138

|

44

|

200

|

50

|

M18X36D

|

|

20

|

50

|

235

|

200

|

163

|

168

|

48

|

240

|

60

|

M22X45D

|

VERTICAL LOADING

-

For Platen without T-slots and the sizes of mold are variable.

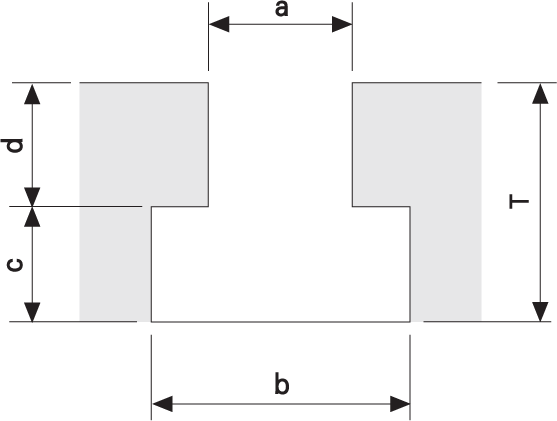

Suggested dimension of T-slot | Additional T-slots plated

|

MODEL

|

|

CB-2

|

|

CB-4

|

|

CB-6

|

|

CB-10

|

|

CB-16

|

|

CB-25

|

|

CB-50

|

|

T

|

a

|

b

|

c

|

d

|

|

32

|

18

|

32

|

14

|

18±0.2

|

|

40

|

22

|

37

|

16

|

24±0.2

|

|

40

|

22

|

37

|

16

|

24±0.2

|

|

44

|

28

|

48

|

18

|

26±0.2

|

|

52

|

28

|

48

|

22

|

30±0.2

|

|

61

|

36

|

56

|

25

|

36±0.2

|

|

84

|

48

|

80

|

36

|

48±0.2

|

-

T: The thickness of additional T-slot platen (min.)

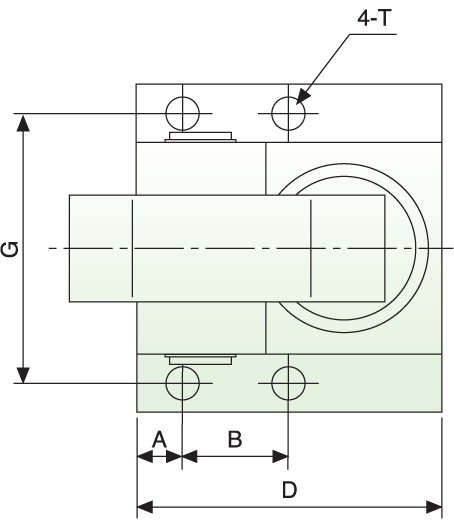

MODEL CB-B

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CB-2B

|

|

CB-4B

|

|

CB-6B

|

|

CB-10B

|

|

CB-16B

|

|

CB-25B

|

|

A

|

B

|

D

|

F

|

G

|

min. E

|

W

|

Tapping (T)

|

|

12

|

35

|

90

|

20

|

84

|

90

|

106

|

M10X20D

|

|

12

|

40

|

110

|

25

|

95

|

93

|

117

|

M12X24D

|

|

15

|

45

|

130

|

30

|

115

|

109

|

140

|

M12X24D

|

|

15

|

55

|

159

|

30

|

135

|

131

|

160

|

M14X28D

|

|

20

|

65

|

200

|

30

|

158

|

142

|

192

|

M16X32D

|

|

20

|

80

|

235

|

30

|

184

|

163

|

218

|

M18X36D

|

VERTICAL LOADING

-

For Platen without T-slot and the sizes of mold is unified.

-

Suggest CB-S for movable platen.

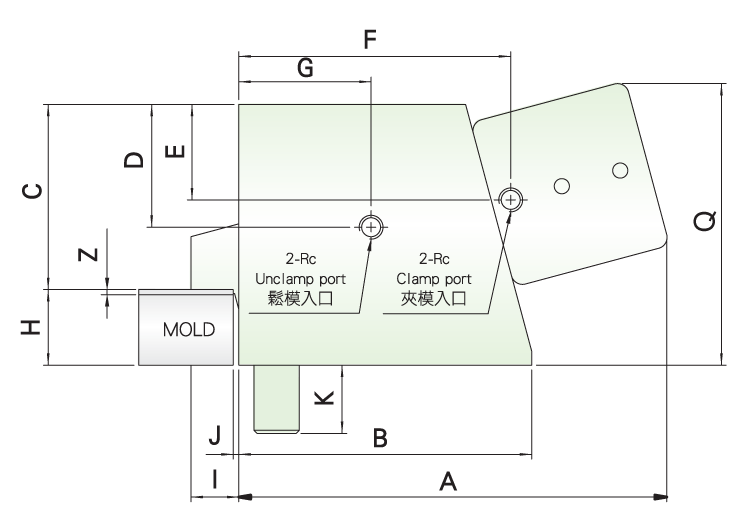

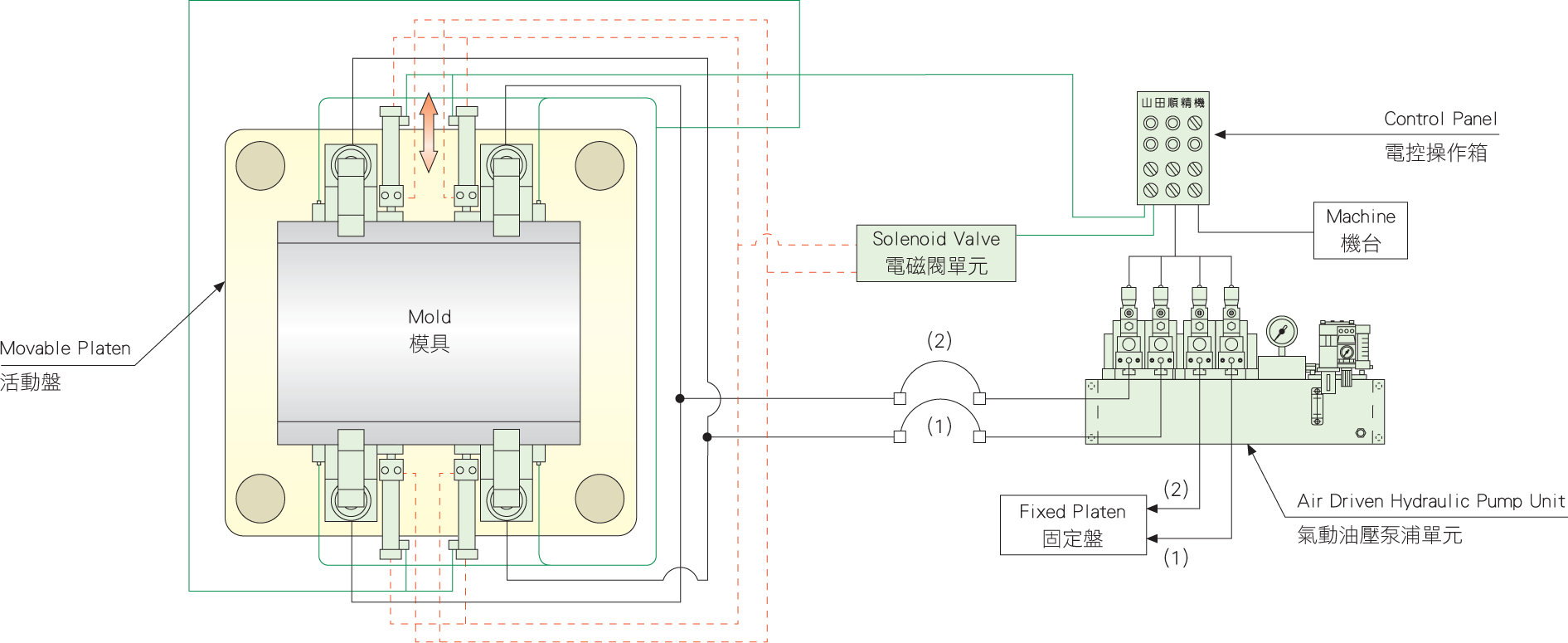

MODEL CG

-

CG Clamp is charactered in mechanical locking system.

The holder of clamp can be shrunk into the clamp when unclamping. It can avoid interference between the holder and mold template.

-

It is only applied on Mold Changer System.

Model Selection

|

①

|

②

|

③

|

④

|

|

The capacity of clamp (4~50 ton)

|

Thickness of template

( H±0.5mm )

|

The direction of piping and wiring connection:

L: on the left side (as below drawing)

R: on the right side

U: on the upper side

|

Sensor voltage:

3: DC10~30V (NPN, 3-Wire)

4: DC10~30V (PNP, 3-Wire)

|

INSTRUCTION OF SPECIFICATION

Unit:mm

|

MODEL

|

|

Clamping force /*tons

|

|

Retaining force /**tons

|

|

Preserved stroke (Z) /mm

|

|

Working temperature /℃

|

|

CG-4B

|

CG-6B

|

CG-10B

|

CG-16B

|

CG-25B

|

CG-50B

|

|

4

|

6

|

10

|

16

|

25

|

50

|

|

0.8

|

1.2

|

2

|

3.2

|

5

|

10

|

|

1.5

|

2

|

|

Max 70℃

|

* Hydraulic Pressure: 140kg/cm²

** No hydraulic pressure

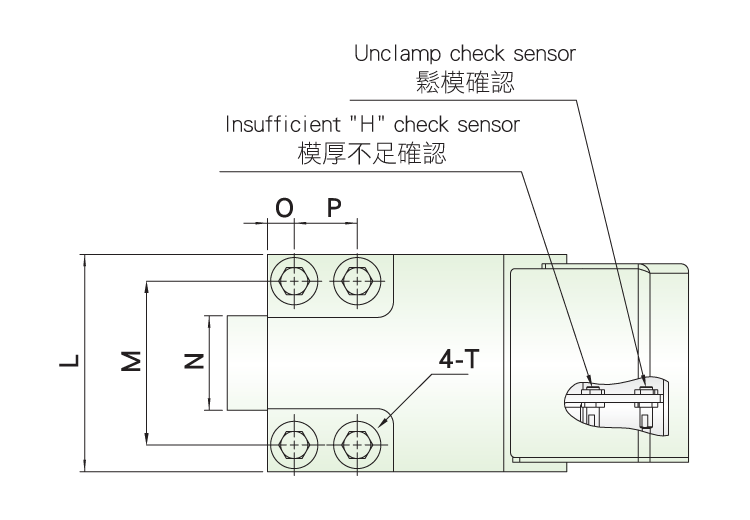

Unit:mm

|

MODEL

|

|

CG-4B

|

|

CG-6B

|

|

CG-10B

|

|

CG-16B

|

|

CG-25B

|

|

CG-50B

|

|

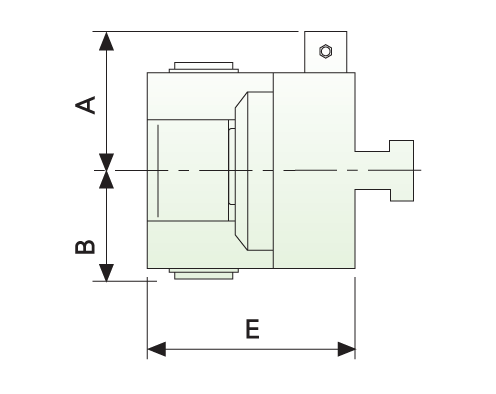

A

|

B

|

C

|

D

|

E

|

F

|

G

|

I

|

J

|

K

|

L

|

M

|

N

|

O

|

P

|

Q

|

Rc

|

H±0.5

|

T

|

|

186

|

123

|

75

|

50

|

30

|

113

|

42

|

17

|

2

|

27

|

90

|

62

|

35

|

14

|

-

|

115

|

1/4

|

25

|

M16

|

|

202

|

140

|

85

|

48

|

36

|

126

|

48

|

19

|

3

|

33

|

110

|

76

|

45

|

17

|

-

|

124

|

1/4

|

30

|

M20

|

|

215

|

150

|

98

|

53

|

42

|

138

|

56

|

23

|

3

|

36

|

135

|

95

|

50

|

20

|

-

|

131

|

1/4

|

30

|

M24

|

|

258

|

190

|

128

|

74

|

53

|

175

|

82

|

28

|

5

|

33

|

138

|

104

|

60

|

17

|

40

|

156

|

1/4

|

30

|

M20

|

|

302

|

240

|

159

|

100

|

64

|

212

|

100

|

33

|

5

|

40

|

170

|

130

|

75

|

20

|

50

|

188

|

1/4

|

40

|

M24

|

|

365

|

290

|

195

|

140

|

88

|

268

|

125

|

35

|

5

|

50

|

215

|

162

|

100

|

27

|

60

|

227

|

3/8

|

50

|

M33

|

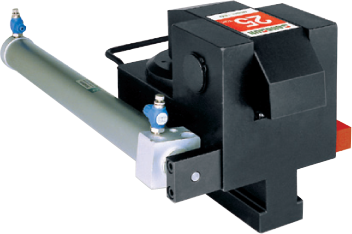

Check Valve Mold Clamp

FEATURE

-

Better safety design clamp.

-

Clamp with Build-in check valve, it can keeps the pressure itself.

-

The clamp will not release, even if the hydraulic tube is damaged.

-

Separate clamp body design, easy for maintain and exchange.

-

Waterproof design for cylinder and piston.

Model Selection

|

①

|

②

|

|

Capacity of Clamp:2-25(tons)

|

-

Empty:Standard type

-

N: With sensor type/DC10~30V (NPN, 3-Wire)

-

C: Pneumatic cylinder movable type

|

INSTRUCTION OF SPECIFICATION

Unit:mm

|

MODEL

|

|

Capacity of Clamp/*tons

|

|

Total Stroke (X)/mm

|

|

Stroke of Clamp (Y)/mm

|

|

Preserved Stroke (Z)/mm

|

|

Total Volume of cylinder/cc

|

|

The tolerance of the template thickness (H) /mm

|

|

CBK-2

|

CBK-4

|

CBK-6

|

CBK-10

|

CBK-16

|

CBK-25

|

|

2

|

4

|

6

|

10

|

16

|

25

|

|

8

|

8

|

8

|

8

|

8

|

8

|

|

3

|

3

|

3

|

3

|

3

|

3

|

|

5

|

5

|

5

|

5

|

5

|

5

|

|

8

|

13

|

22

|

38

|

55

|

99

|

|

±2

|

±2

|

±2

|

±2

|

±2

|

±2

|

*Hydraulic pressure: 24.5MPa (250kg/cm²)(3550psi)

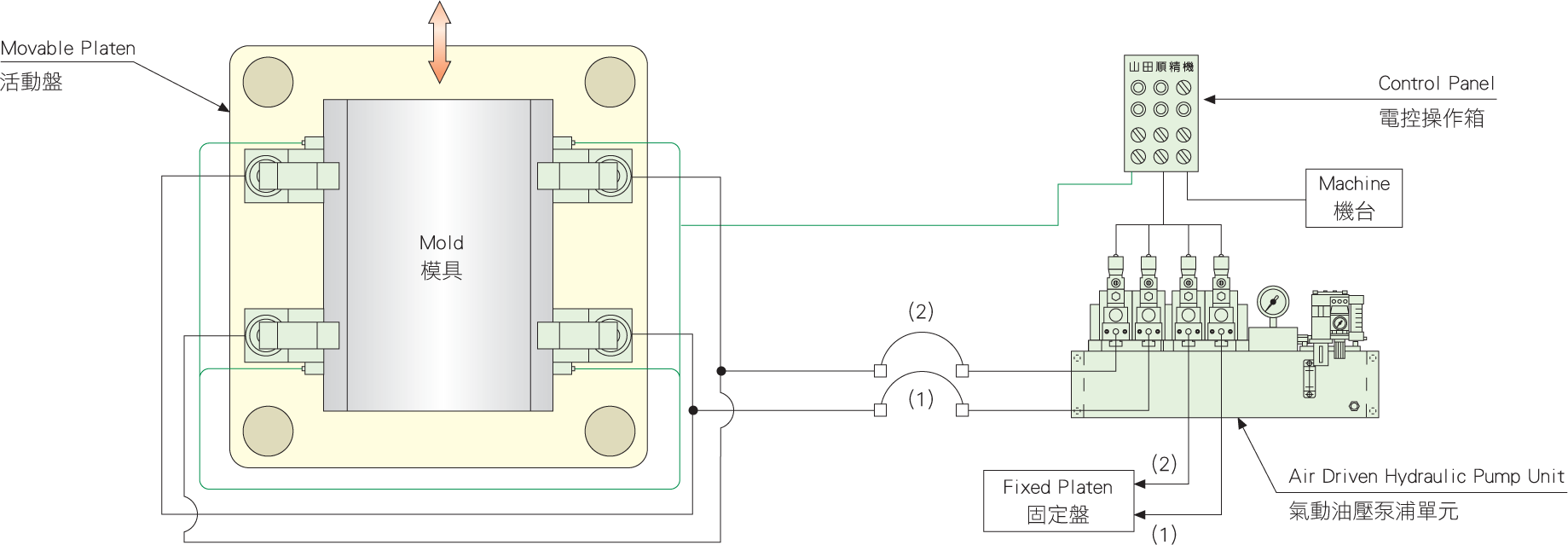

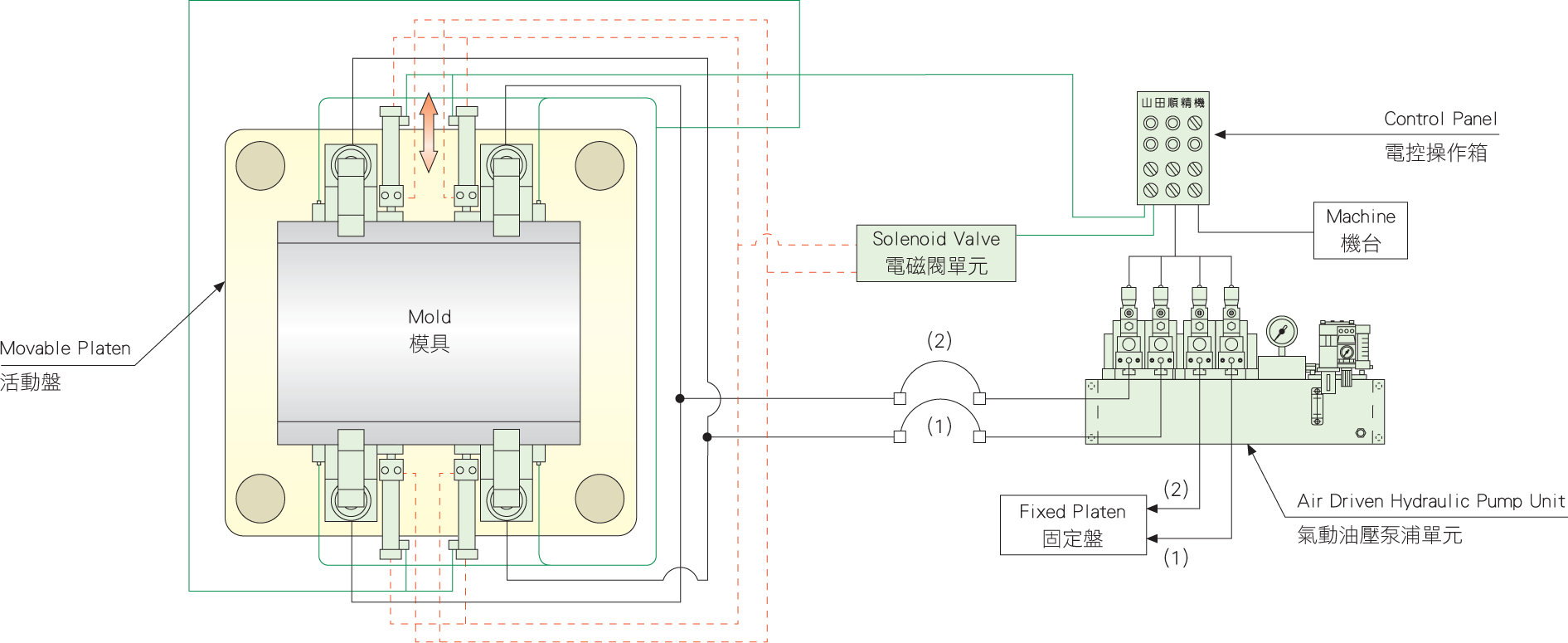

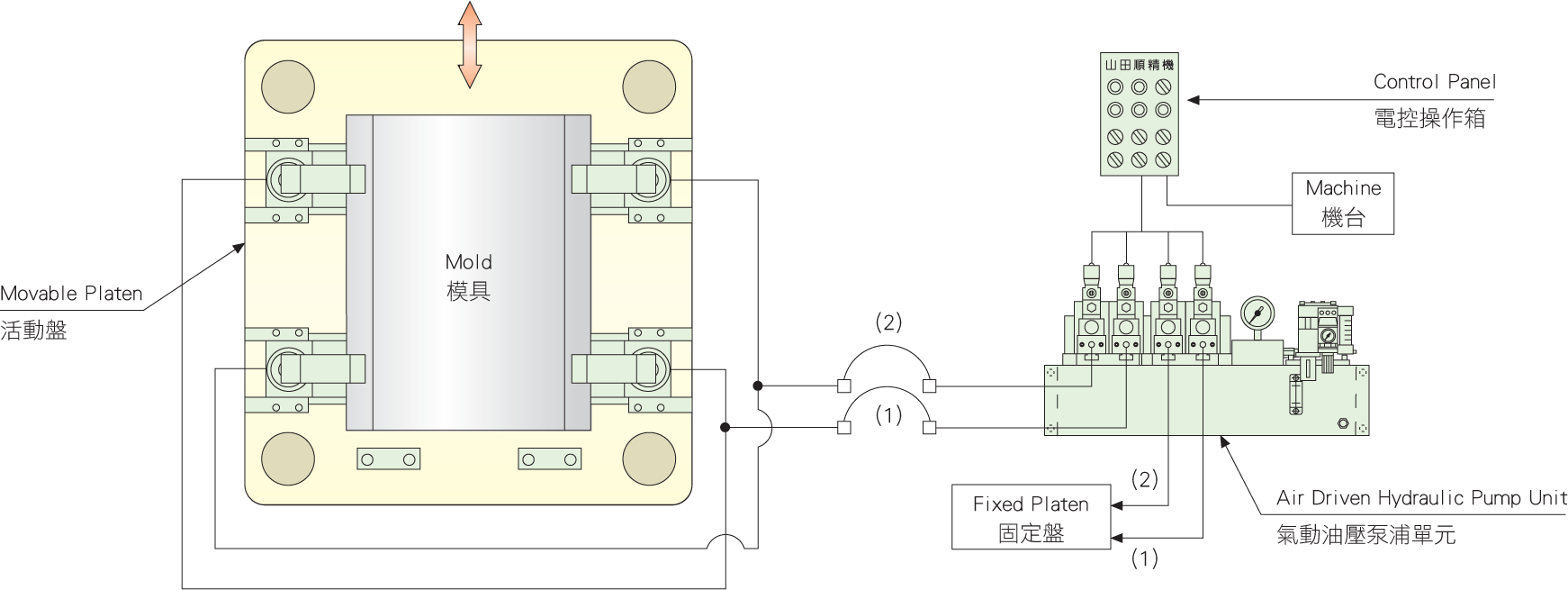

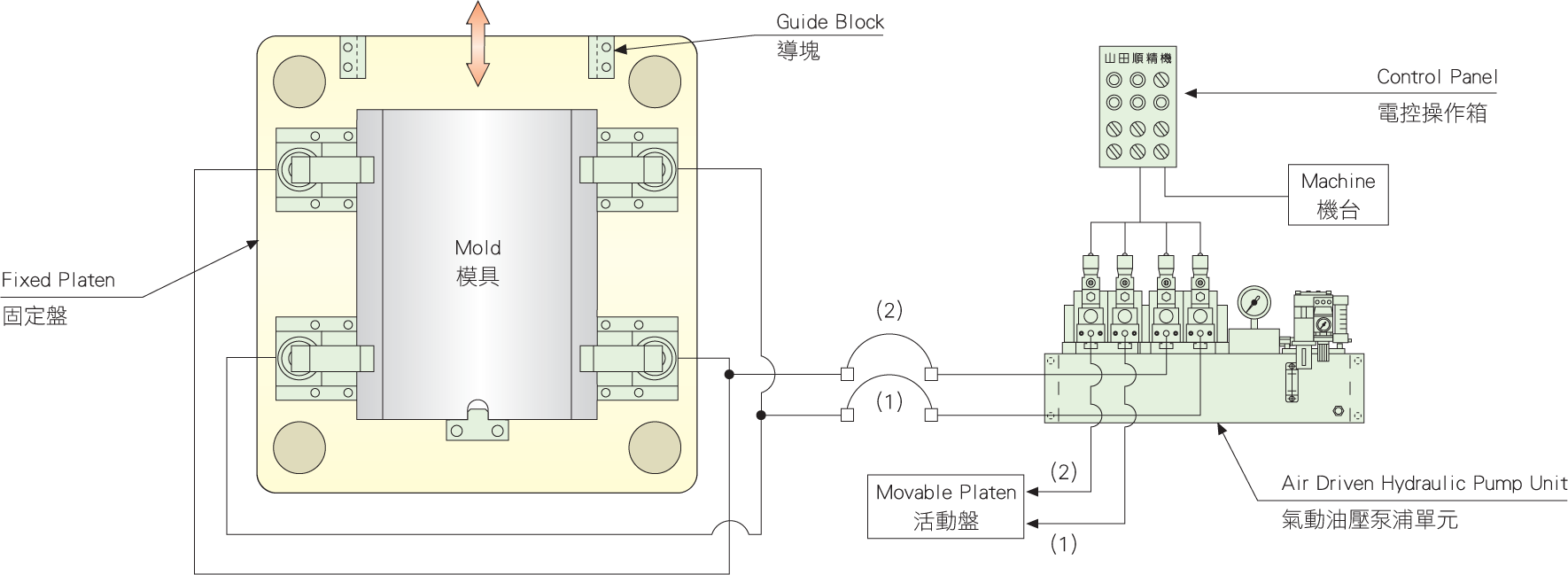

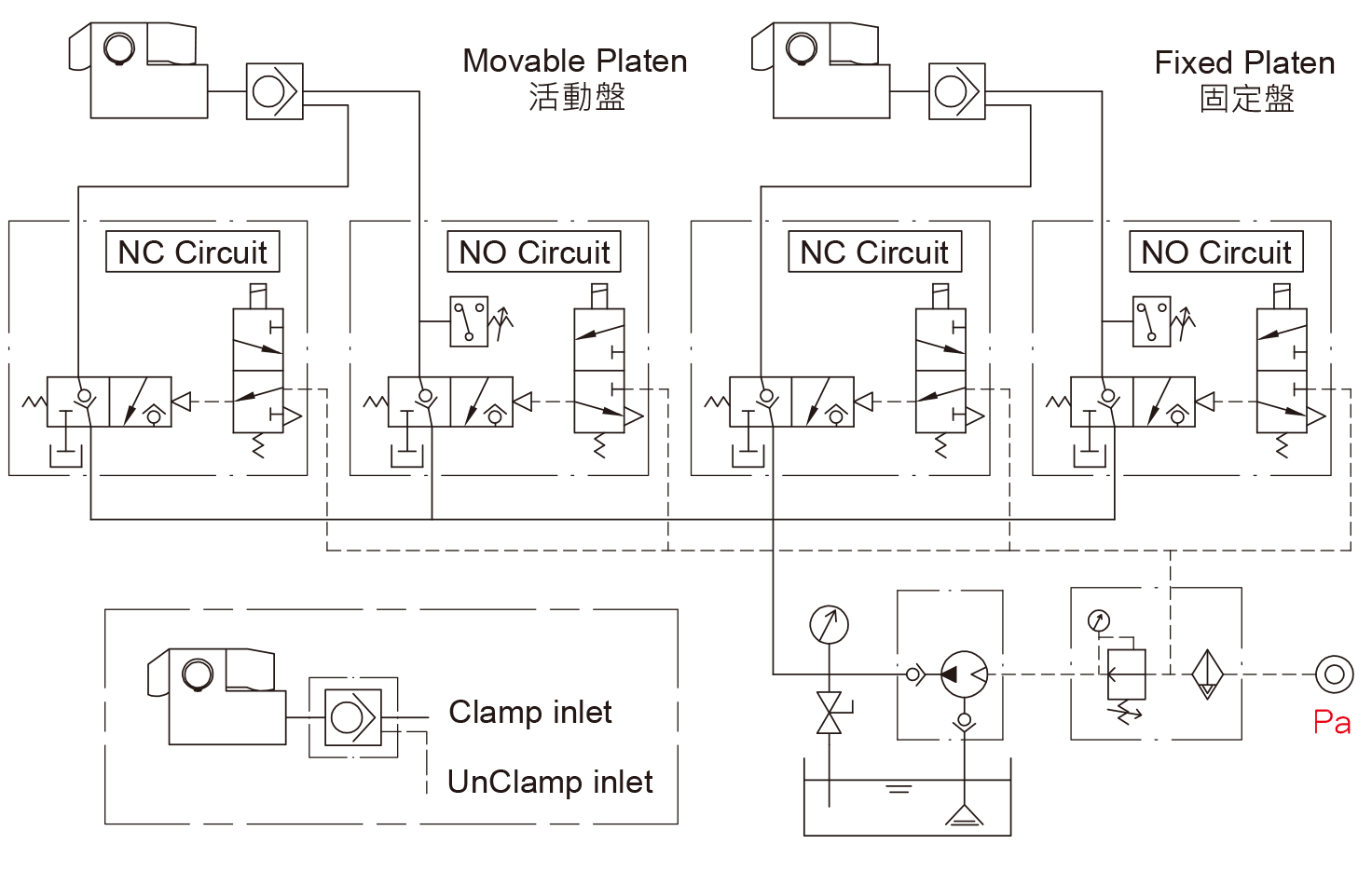

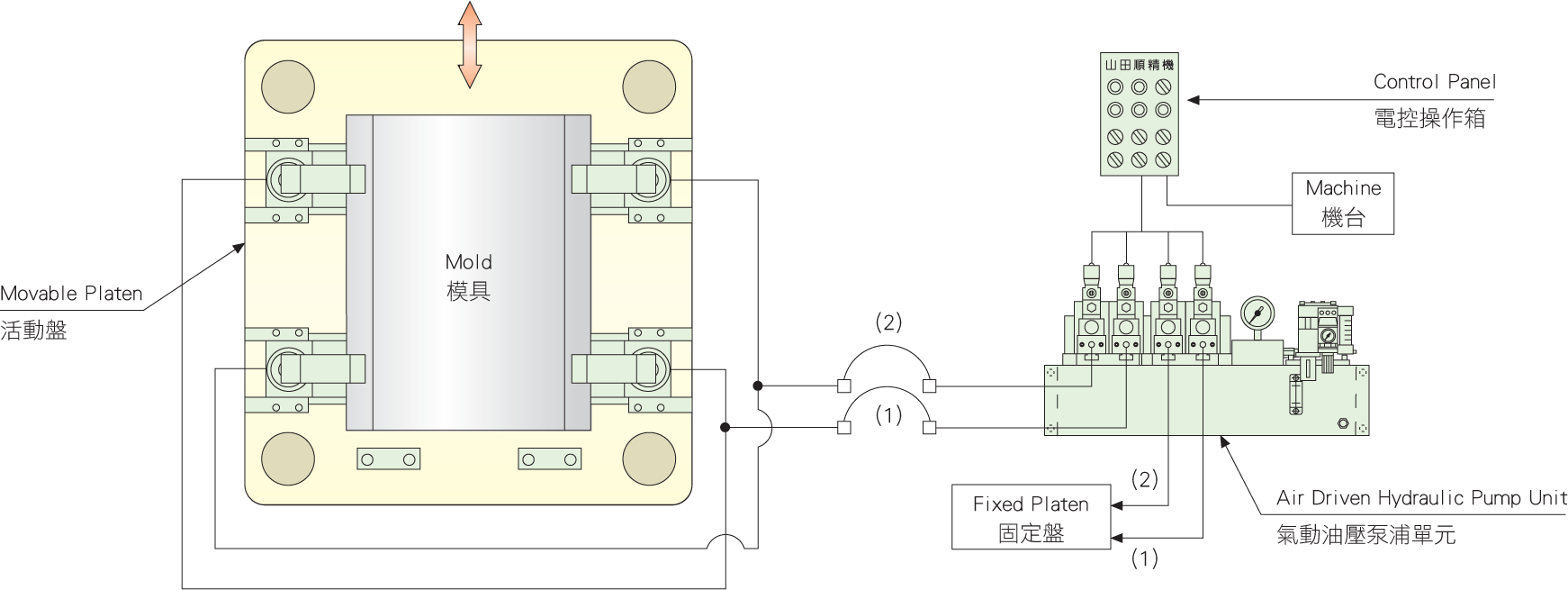

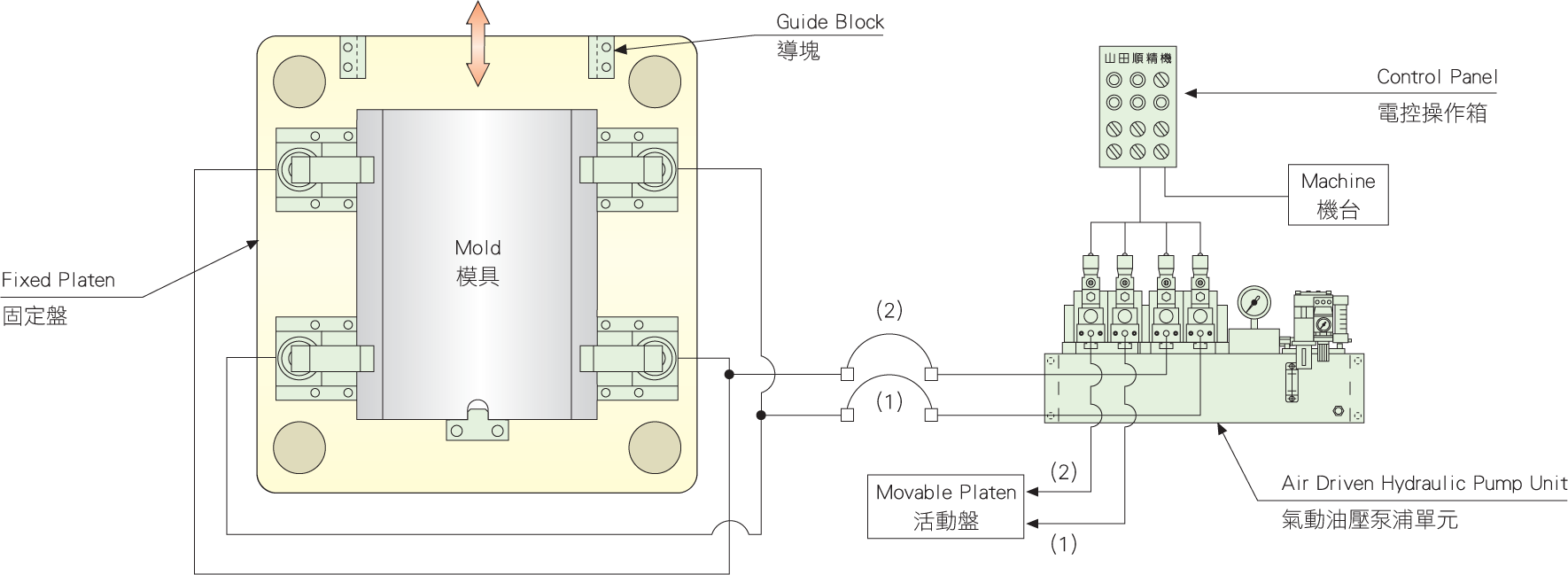

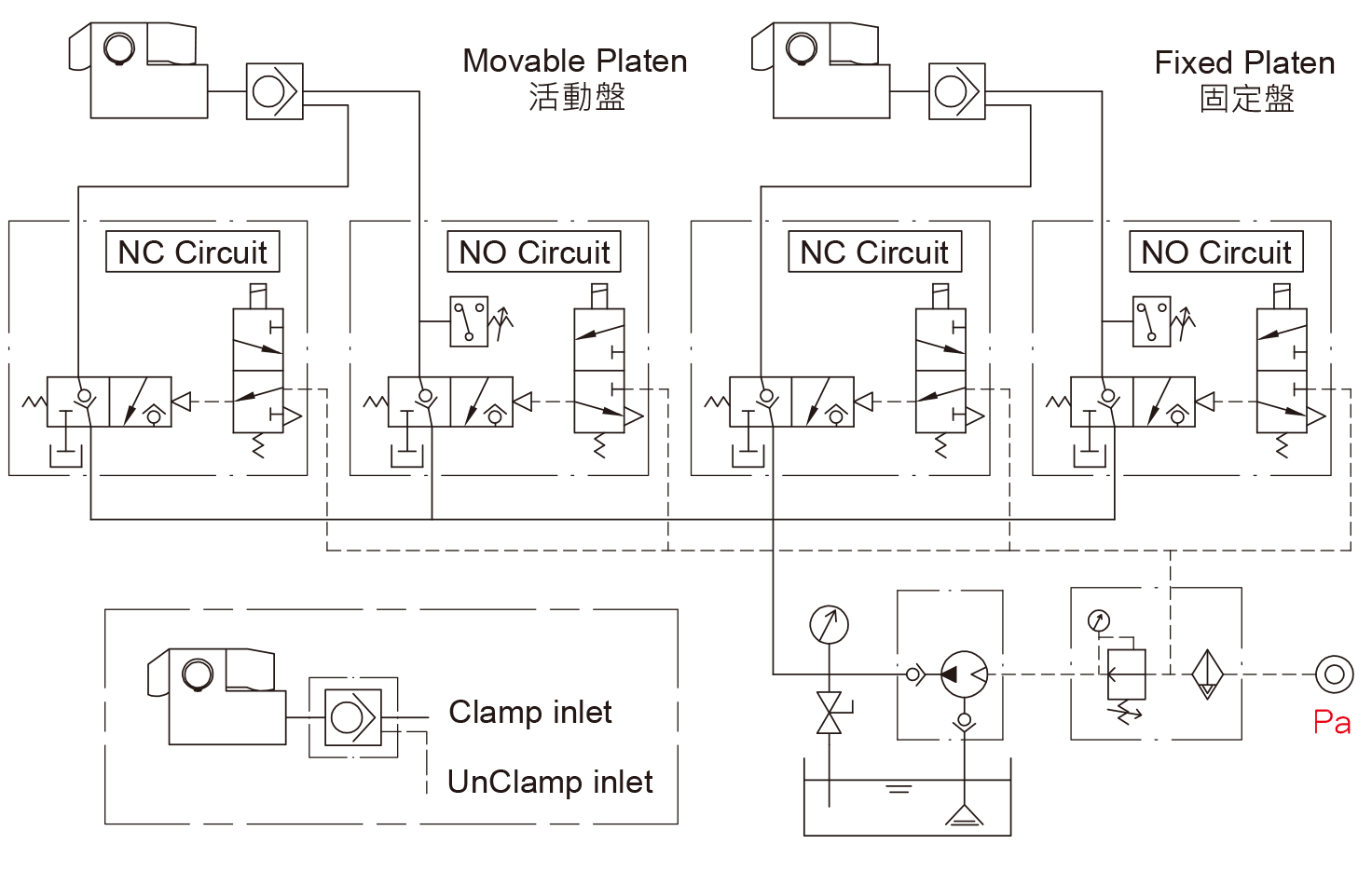

CIRCUIT CONTROL SYSTEM

MODEL CBK

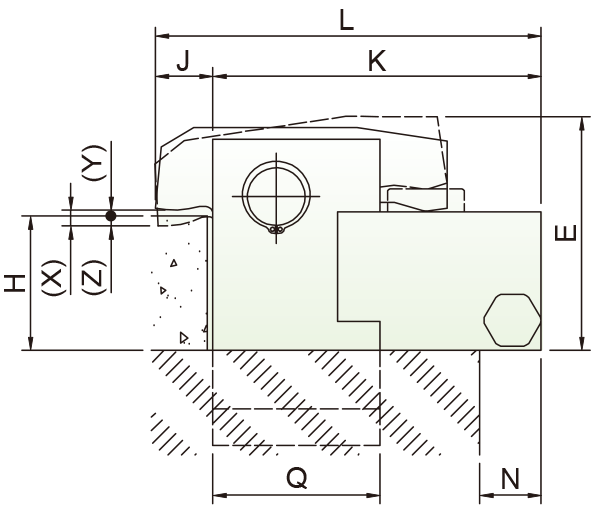

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CBK-2

|

|

CBK-4

|

|

CBK-6

|

|

CBK-10

|

|

CBK-16

|

|

CBK-25

|

|

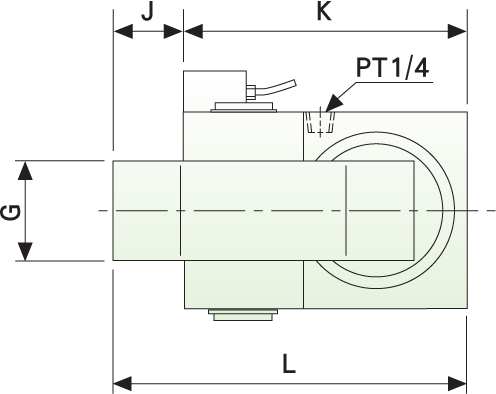

min.C

|

min.E

|

F

|

G

|

I

|

J

|

K

|

L

|

max. N

|

Q

|

|

10

|

73

|

68

|

32

|

9

|

20

|

106

|

126

|

15

|

46

|

|

12

|

85

|

79

|

40

|

9

|

24

|

124

|

148

|

20

|

61

|

|

14

|

100

|

96

|

46

|

9

|

29

|

149

|

178

|

25

|

80

|

|

16

|

119

|

117

|

54

|

8

|

30

|

171

|

201

|

30

|

87

|

|

20

|

133

|

129

|

58

|

8

|

30

|

202

|

232

|

35

|

108

|

|

23

|

150

|

156

|

70

|

8

|

30

|

235

|

265

|

40

|

128

|

MODEL CBK-N

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CBK-2N

|

|

CBK-4N

|

|

CBK-6N

|

|

CBK-10N

|

|

CBK-16N

|

|

CBK-25N

|

|

A

|

B

|

G

|

J

|

K

|

L

|

|

52

|

56

|

32

|

20

|

106

|

126

|

|

57.5

|

39.5

|

40

|

24

|

124

|

148

|

|

70

|

48

|

46

|

29

|

149

|

178

|

|

80

|

58.5

|

54

|

30

|

171

|

201

|

|

85.5

|

64.5

|

58

|

30

|

202

|

232

|

|

99

|

78

|

70

|

30

|

235

|

265

|

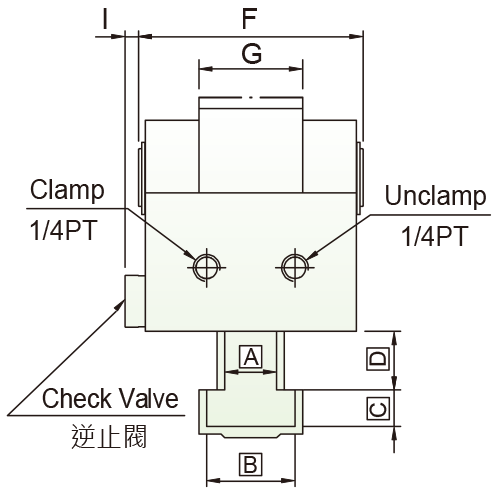

MODEL CBK-C

OUTLINE DIMENSIONS

Unit:mm

|

MODEL

|

|

CBK-4C

|

|

CBK-6C

|

|

CBK-10C

|

|

CBK-16C

|

|

CBK-25C

|

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

K

|

L

|

Rc

|

Tapping (T)

|

|

58

|

73.5

|

29

|

46.5

|

20

|

57.5

|

73.5

|

124

|

131

|

1/8

|

M6 X 12D

|

|

70

|

86

|

34.5

|

55

|

24

|

61.5

|

82

|

149

|

135.5

|

1/8

|

M6 X 12D

|

|

80

|

104

|

41.5

|

66

|

30

|

49

|

101

|

171

|

130

|

1/8

|

M8 X 16D

|

|

86

|

119.5

|

52

|

73.5

|

36

|

50

|

112.5

|

202

|

141

|

1/8

|

M10 X 20D

|

|

99

|

139

|

63.5

|

88

|

40

|

65

|

138.5

|

235

|

168

|

1/4

|

M10 X 20D

|